7 Steps to Safer Work Zones: Traffic Control Services for Asphalt Projects

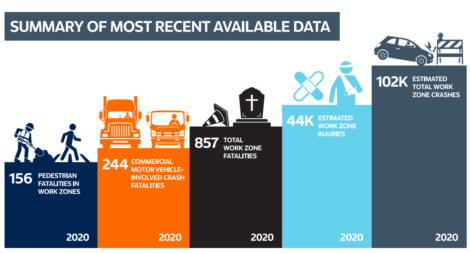

Work zone crashes on highways and roadways continue to be a major public safety concern per U.S. Department of Transportation (DOT) data. From 2016 to 2020, there were more than 154,000 injuries due to crashes in work zones, representing an average of 84 per day. Over that same time, more than 4,000 fatalities—two per day—have occurred in work zones.

The data also shows that work zone crash fatalities decreased by about 18% over this time and, while the trend is heading in the right direction, there is clearly a need for increased emphasis on safety. Enter professional traffic control services that focus on reducing the number of accidents and injuries that occur in work zones.

*Source: Fatality Analysis Reporting System (FARS), National Highway Traffic Safety Administration, U.S. Department of Transportation

Data from the National Work Zone Safety Information Clearinghouse shows how daily changes in traffic patterns, narrowed rights-of-way and other construction activities can create a combination of factors resulting in crashes, injuries and fatalities. From 2016 to 2020, the average number of crashes in work zones was over 115,000 per year.

Take Control of Safety

Every work zone is different and asphalt contractors must approach each job as its own challenge when it comes to protecting people and progress. Properly planned and monitored work zones help to minimize the likelihood of fatalities and life-altering injuries by eliminating at-risk behaviors for motorists and workers alike.

Asphalt paving and patching assignments have the potential to be extremely hazardous because of the presence of heavy equipment and the large volume of vehicles in the work zone. Effective traffic control measures can provide clear warning and direction to motorists approaching a construction area. Increasingly, these measures benefit from a range of new technologies that are helping to make roads even safer.

Here are just a few of the advantages that contractors can gain from implementing effective traffic control procedures:

- Less Risk. Traffic control methods and devices provide better visibility to drivers and pedestrians by helping to keep lines of sight clear and unobstructed. This is especially important as large equipment like asphalt pavers can potentially obstruct a driver’s view and make it difficult to see hazards ahead.

- Fewer Distractions. High-visibility work zones also help to minimize the potential for distracted driving habits that can take motorists’ attention off the road. Zones must be designed in such a way as to break through the clutter of permanent signage, commercial surroundings and other visual cues that drivers are accustomed to.

- Reduced Liability. A comprehensive traffic control plan also helps asphalt contractors reduce their liability exposure as it lessens the chance of accidents and injuries occurring. Whether crews are patching pavement, marking defects or closing down lanes, motorists must be alerted to the activity.

7 Steps to Safer Work Zones

When implementing traffic control measures for an asphalt paving or patching project, the following best practices can help to ensure the safety of workers and the public:

Plan Ahead. No two work zones are identical, meaning preparation is key to safety. Different traffic control services may be required for short-term and large-scale projects. A simple patching assignment, for instance, will typically have fewer considerations than when laying down miles of mat. Along with signs and signals, asphalt contractors may need to incorporate message boards, lane usage devices and other technologies to direct drivers. Careful planning and coordination between contractors and traffic control services can help to limit both the size and complexity of a work zone so that drivers can get to their destinations safely in the shortest time. It is also important to set up work zones and traffic control devices at least one day before the project begins so that everything is in its rightful place and confirmed to be properly functioning.

Train Employees. Contractors should make sure that all of their employees are properly trained with a basic understanding of work zone construction hazards and the importance of internal traffic control. This can sometimes include the correct setup and use of traffic control devices. The National Asphalt Pavement Association (NAPA) offers training to increase safety awareness for crews, truck drivers and equipment operators working in roadway construction zones. NAPA’s CrewSafety Work Zone Training helps employees recognize unsafe situations and understand how they can proactively ensure their well-being. Additionally, many professional traffic control service providers offer convenient access to educational resources. In all cases, only crew members who have been properly trained should be permitted to enter the work zone.

Brief Crews Daily. Critical to any construction project is a daily pre-job briefing led by the site safety supervisor. This will include a review of work zone conditions, safety protocols and escape routes. It is also the best time to discuss any accidents or near-misses reported the day before in order to prevent a reoccurrence. Hazards in proximity to the work zone—obstructions to visibility, commercial activity and many other factors—can change overnight and therefore a briefing should be completed at the start of each day. In some cases, it may be necessary to devise a new safety plan should the work or environment change significantly, or as additional hazards are identified.

Employ Devices. It is also important to choose the right type of traffic control devices, such as warning signs, cones, barricades, flags and reflectors, in order to set up a work zone for optimal safety. The type of device and placement must comply with guidelines set forth in the Federal Highway Administration’s Manual on Uniform Traffic Control Devices (MUTCD) as well as any state or local traffic control ordinances. The latest technologies can also offer a safer approach to traffic management. Automated Flagger Assistance Devices (AFADs) are popping up on roads everywhere as contractors realize the many benefits of autonomous operation and/or remote control of traffic signaling from a safe distance. AFADs can automatically instruct traffic to stop or proceed, with some models having the ability to sound an alarm should a vehicle violate the boundaries of the work zone. Others incorporate high-resolution security cameras to capture incidents—this can help to shield contractors from liability claims in the event of an accident.

Monitor Constantly. It is important to monitor the work zone regularly to ensure that the setup is correct and warning devices are still in their rightful place and functioning properly. If any changes are required, they should be made immediately. Continual supervision is also key to ensuring the safety of workers and the public. Work sites should have a qualified traffic observer (a protector) to monitor changing conditions and to warn crews to dangers. An observer is also needed to protect workers who are setting up or removing temporary traffic control devices.

Stay Alert. Constant vigilance is required to recognize dangerous traffic situations in work zones. Personnel should be trained—and continually reminded—to wear appropriate visual/audio traffic control Personal Protective Equipment (PPE), to never turn their back on traffic and to frequently check their position for routes of escape. For AWP Safety traffic control supervisors, it is standard practice to use a storm whistle to alert others to potential dangers. In noisy construction zones where volumes can be deafening at times, the high pitch of a storm whistle can rise above the clamor, whereas the sound of someone shouting may be drowned out.

Stop Work. The safety of people is more important than any project deadline. Crews should stop work immediately if the necessary resources are not present and/or available, such as a lack of personnel, insufficient number of traffic control devices, or improper or malfunctioning equipment. Work should also stop immediately if the on-site traffic control supervisor cannot safely perform their tasks for any reason, or if that person perceives any condition that poses imminent danger to people, equipment or the environment. Following a stop work event, it is important to ensure the well-being of affected workers and to notify management per incident reporting procedures.

Ensuring Everyone Makes It Home

Additional to these important steps, the assistance of a professional traffic control services provider can help asphalt contractors significantly reduce the risk of accidents and injuries. Services administered by trained and certified personnel whose full-time job it is to ensure safety can benefit any project in terms of efficiency and consistent application of best practices.

When choosing traffic control services, it is important to select a provider that is experienced and reputable, and who knows the local regulations and guidelines. The chosen provider should also be able to coordinate with local police departments and transit authorities to arrange for law enforcement assistance when needed (a uniformed officer can enhance motorist awareness of work zones) and to ensure that affected businesses and residents are notified of the disruption prior to the start of the project.

By planning ahead and taking the necessary precautions, the risks of work zone accidents can be minimized, creating a safer environment for all.

Looking to learn more about how AWP Safety can help support your next asphalt Traffic Control project? Request a Quote and our dedicated sales team will be in contact within 24 hours.